It Ain’t About The Platform!

As a manufacturer, if you take a look around the internet, you'll see all manner of software platforms designed to help you collect, extract, manipulate, store and display information from your various manufacturing systems.

Welcome to episode six of a fourteen-part series by John Broadbent from Realise Potential.

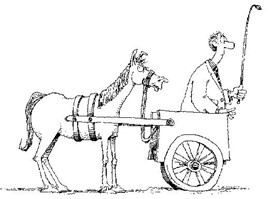

What I'm experiencing though, is a reluctance for manufacturers to jump in and get started, and I've realised there are several reasons for this, which I'd like to share with you here because I've realised it's not about the platform at all. To use a metaphor, you can't put the cart before the horse.

What I'm experiencing though, is a reluctance for manufacturers to jump in and get started, and I've realised there are several reasons for this, which I'd like to share with you here because I've realised it's not about the platform at all. To use a metaphor, you can't put the cart before the horse.

Before you head down the path of considering an investment in any IoT, IIoT or Industry 4.0 platforms, I'd like to explain why it's of paramount importance you ask yourself and your organisation a few key questions.

With Cisco research showing 75% of IoT projects are failing, better to ask these questions first to ensure you're in the 25% that succeed.

The first question that needs to be answered is this, "Do you want to be Best-In-Class?"

If the answer to this first question is no or not sure, then why are you considering investing in a platform in the first place? You might gain some initial advantage but chances are it'll be a project that fails, the reasons for which are in the Cisco report.

If the answer is yes, then the next question is, "Do you know what Best-In-Class looks like today, in a modern, smart factory environment?"

I've heard many organisations say they know, yet talk with the people themselves and I often find they wouldn't know what Best-In-Class looked like if it bit them on the butt!

This is especially true where what I call the grey-haired ceiling is in place with a management team that's been there for 20+ years, so they've not been exposed to these modern concepts.

Under these circumstances, a platform-centric approach or any other Industry 4.0 initiative has a very low chance of success.

In one of my earlier videos, I mentioned the critical alignment between People, Systems and Processes, and the only way to ensure this is through effective leadership, so the third question is, "Do you have a committed leadership that understands Industry 4.0 and is fully supportive of digital transformation, and willing to embrace the learnings from failure along the way?"

Or is it a risk-averse, finger-pointing, lack of accountability, siloed culture where everybody plays it safe and failure is rewarded with carpeting or DCM, a three-letter acronym for Don't Come Monday?

By now, I hope you can see where I'm going with this line of questioning.

If you get to this point and all of your ducks are in a row, CONGRATULATIONS! You're way ahead of the pack and in a very small percentage poised to capitalise by being an early adopter.

At this point, the fourth question therefore is, "Do you have a list of projects with returns on investment, an implementation plan with expected staged outcomes, an understanding of what you have already in place, where you'll need to invest, the level of that investment and when it'll fall due on the implementation timeline?"

This then leads to the fifth question, which is, "Where is my immediate low-hanging fruit, both in terms of cost and return", in other words, where's the biggest bang for my buck?

Out of this question comes an opportunity for a pilot project or proof-of-concept, and an understanding of whether you have alignment between people, systems and processes.

If you do, happy days! If not, you know what to do to get that alignment, and PLEASE don't underestimate this previous point. I've listened to many businesses tell me that the factory automation team is working on multiple IIoT projects, yet none of them are delivering nor impacting on what the Board thinks are the most important issues.

Sad but true, and again simply because of lack of alignment.

Question six then is, "Do you have the requisite skills, bandwidth, cross-departmental collaboration, maybe a steering committee, and budget?"

As you can see, we're well down the decision tree by now with exits at every level, or work to be done at each level, to move forward and get to the final question, "Have you done your research, interviewed and selected a platform partner?"

This could be a systems integrator or a platform vendor themselves, such as Microsoft, AWS, PTC, Schneider, Google, IBM ... there are so many to choose from, however, be very careful of hammers looking for nails and sales hype around how "We're the best."

You may also consider choosing a trial platform and working with the vendor on a proof-of-concept project, conditional on its success, as long as you agree on what success looks like and on any future relationship.

Remember though, Caveat Emptor!

So, to recap:

- Do you want to be best-in-class?

- Do you know what best-in-class looks like?

- Do you have leadership committed to digital transformation?

- Do you have a high-level project opportunity list?

- Do you have an implementation timeline with low-hanging fruit coming first?

- Do you have the skills, bandwidth and budget?

- And finally, have you chosen an implementation partner?

I hope you can see now why it's not about the platform after all, but a series of steps of methodical inquiry, which will clarify the maturity level of your business along this decision tree, and at which level work still needs to be done.

With several successful smart factories under my belt, I can assure you it is worth the focus, time and investment, so if you need help creating a strategy and setting a course to become Best-In-Class, you can reach out to me on LinkedIn or via the Realise Potential website.

In the meantime, stay safe and well and may all your production be profitable!

John Broadbent

Watch John's original LinkedIn video here.

.png?width=190&name=IPA%20Logo%20Transparent%20(Hi-Res).png)