As a manufacturer, if you're not familiar with the concept of LEAD measures, let me share with you why they're important by comparing them to what most businesses rely on, which are lag measures.

Welcome to episode eight of a fourteen-part series by John Broadbent from Realise Potential.

Simply put a LAG measure is at the end of a process, usually after some conversion of something into something else. For example, profit and loss, also known as P&L, is a lag measure for a business, often days or even months after the event.

Values like yield, variance to standard, labour utilisation and EBIT are also lag measures.

So what is a lead measure?

Before I go into lead measures, I want you to imagine driving your car without a dashboard, the windows blacked out, the scene in the rearview mirror where you were last week, and the boss in the passenger seat asking, “Are we there yet?”

I'm sure you'd agree, you'd never drive your car like this, so why do we allow our businesses to run this way?

If we look to the past, the technology to get data out of processes, in real time, simply wasn't there. However, today it is, as long as we've purchased the right open-source equipment, got it on our network and know-how to get the information we need out of it.

In my last Episode 7 about the secret sauce of smart factories, I discussed integration. If you're a manufacturing business that has the precursor steps in place and gone down the integration path, it's now time to explore the next step, which is all about extracting value, since so far, the initial steps have required investment.

Cost justification is a big issue for most, especially when CapEx funds are tight and return on investment requirements can be downright unrealistic. How about a business I know whose ROI is just eight weeks and no assurance of what such investment will return anyway?

There's an excellent PDF report from Acatech entitled "Industry 4.0 Maturity Index." This little gem in the report encapsulated for me, how real-time data and lead measures can provide significant value via what's known as time compression.

I'll use an example from the food industry where real-time data capture really comes into its own, as I think it's one we can all relate to.

Let's say at some point in time, an event happens that creates a problem product. For example, the wrong packaging or label is being put on the product.

Can't happen in your business you think? Well, think again!

Did you know that 30% of food recalls are from undeclared allergens often meaning incorrect packaging and labelling?

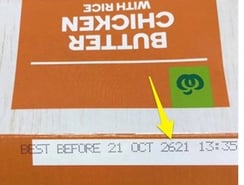

Here's one that slipped through to the keeper with a use-by-date of 2621. Wow! That's some shelf life!

Here's one that slipped through to the keeper with a use-by-date of 2621. Wow! That's some shelf life!

In our case, the wrong sleeve was put on the wrong product. It ended up in a shipper and found its way to the supermarket shelf. Mr Jones bought his butter chicken only to discover when he got at home and took it out of the packet that it's actually Chicken Saté, a significant peanut allergen risk!

Mr Jones decided he wanted his money back because his children can't eat peanuts and he wanted to ensure no one else got hurt, so he took it back to the supermarket.

This initiated a recall due to undeclared allergens, resulting in a significant fine for the producer of some $100,000, plus full replacement of the recalled product and perhaps a deep level audit with a significant red mark, and of course, brand reputation damage.

Let's take a look at what happened here.

The event happened sometime in the past. The customer's insight was that the labelling on the pack wasn't what was in the pack. Mr Jones read the packaging, ‘analysis’, and then decided something was wrong, so he took ‘action’ and returned it to the store.

The latency between the event, wrong packaging applied, and the action, return to store, could be weeks, and this is where the value loss occurs in this case, $200,000 for the combined fine and ‘make good’, is not uncommon.

How could this be different in a lead measure, integrated real-time world?

This next example is actually from a smart factory installation I helped build back in 2015.

Someone puts the wrong sleeve on the product .. that's the event.

The inline inspection system reads the barcode (insight). It analyses the code and finds it to be incorrect and it decides to stop the line, with a fault on the system telling an operator that it had seen an “Unexpected GTIN”.

In this example, the time compression has now gone from weeks to typically seconds, so the value loss has been significantly reduced.

This works because master data from the business's ERP system, in the form of production orders, is electronically sent to the site manufacturing execution system, which then sends specific data to an inline packaging and label verification system, all in real time.

Once an order is selected for the packaging operation, the check weigher, metal detector, scanner and date coder are all set from ERP master data.

It's an integrated system!

As packets of food travel past a sensor, the barcode reader ensures the correct GTIN, and if correct, tells the inkjet coder, what Use By Date to print.

One source of the truth, no human intervention, no mistakes.

Ironically, the implementation of such an integrated system will pay for itself three times over with the prevention of just one recall, let alone the brand damage.

Yet, I know of many companies who refuse to make such an investment and choose to run the gauntlet instead. It simply doesn't make sense to expose the business to such risk.

Of course, these systems only work when disparate systems found on factory floors, can actually talk with each other and share information, so if you missed Episode 7, check it out.

If you need any help or clarification on how to time compress your manufacturing business and become more LEAD measure driven, you can reach out to me on LinkedIn, or via the Realise Potential website. Until next time, may all your production be recall-free!

John Broadbent

Watch John's original LinkedIn video here.

.png?width=190&name=IPA%20Logo%20Transparent%20(Hi-Res).png)