Robotic Palletising Benefits and Line Improvements

.jpg?width=317&name=086A1998%20(1).jpg)

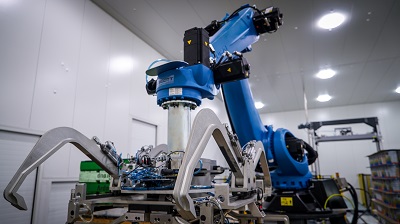

Palletising in any manufacturing plant presents many operational challenges, from production efficiencies to safety considerations.

Manual palletising methods are notoriously labour intensive, time consuming and plagued with the occupational health and safety issues associated with heavy lifting. If the palletising task requires heavy manual handling, those operational challenges become particularly prudent. In order to improve worker safety standards, productivity and generate labour cost savings, many manufacturing plants have turned to robotic palletising systems.

.jpg?width=218&name=086A2069%20(1).jpg) Robotic palletisers provide continuous operation during production processes with the robot picking a product and placing it onto the pallet directly. The entire system is automatic, requiring minimal input from the line operator, ensuring a safer and more efficient process. Robotic palletising can be added as either in-line or end-of-line configurations, whichever is most beneficial to the overall process. Safety systems such as guarding and light curtains further improve the system for use near human workers while maximising the clear area inside the cell ensures free access around the robot and conveyors, allowing for cleaning, maintenance and general operation.

Robotic palletisers provide continuous operation during production processes with the robot picking a product and placing it onto the pallet directly. The entire system is automatic, requiring minimal input from the line operator, ensuring a safer and more efficient process. Robotic palletising can be added as either in-line or end-of-line configurations, whichever is most beneficial to the overall process. Safety systems such as guarding and light curtains further improve the system for use near human workers while maximising the clear area inside the cell ensures free access around the robot and conveyors, allowing for cleaning, maintenance and general operation.

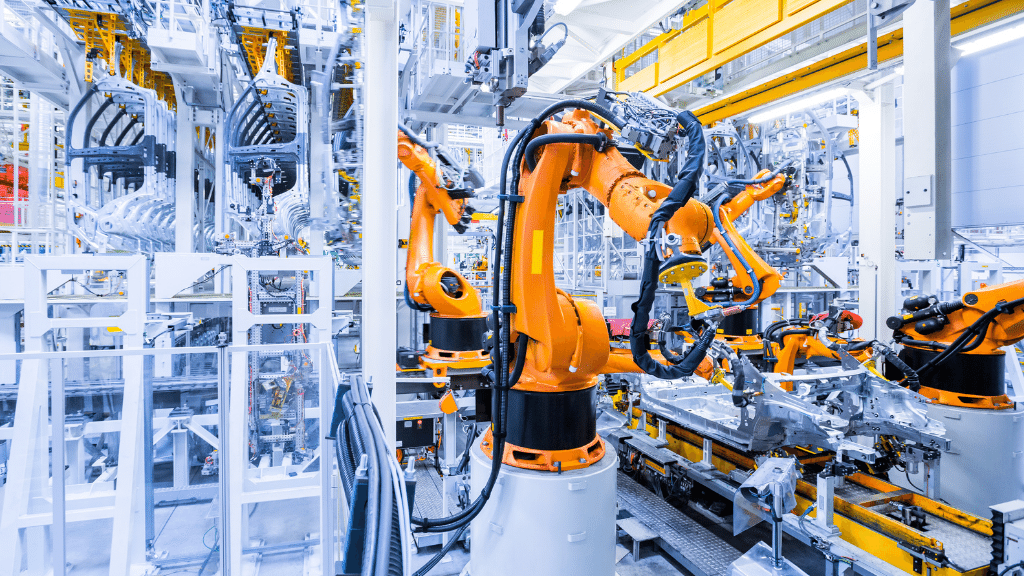

A robot control system with a palletising function makes it possible to load and unload a variety of products without spending a lot of time on programming or teaching. The customisable nature of robotics means that the range of article types as well as dimensions and materials of the packaging units are virtually unlimited. Cartons, Trays, Bags and a wide variety of containers can be picked and palletised, whether on pallets or pushcarts, right on schedule and with minimal errors. With advancements in end of arm tooling (EOAT) and automatic tool changers, flexible robot palletising work cells have been introduced to many factory floors and while they’re still the primary domain of the food packaging and processing industries, their applications are wide reaching.

.jpg?width=200&name=086A2055%20(1).jpg) Palletising Robot Benefits:

Palletising Robot Benefits:

- Elimination of all manual handling during palletising operations

- High speed palletising for single product types

- Flexible palletising, customisable to suit any desired pallet and product configurations

- An increase in overall production capacity

- Robotic systems have the capacity to transfer up to 120kgs mass

- Improved safety for workers

- Low initial cost and fast payback period

- Improved production efficiency

Scott & Automated Palletising

Scott offers everything from the latest robot technology on the market, to low cost palletising options, meaning enterprises of all sizes can improve productivity, efficiency, and even employee health, safety, and motivation. Scott robotic palletising systems are built in our workshops and fully tested prior to installation, minimising downtime during cutover and ensuring a smooth set up during installation. This also means that our systems can be integrated into any line and in almost any project. Our team are also experts in their fields, offering top quality engineering, high safety standards and 24/7 service and support in Australia. Contact Scott today to have a chat about how robotic palletising can improve your company’s output.

Related content: robots in the workplace

.png?width=190&name=IPA%20Logo%20Transparent%20(Hi-Res).png)