The Unforeseen Benefits of Adding Robots in the Workplace

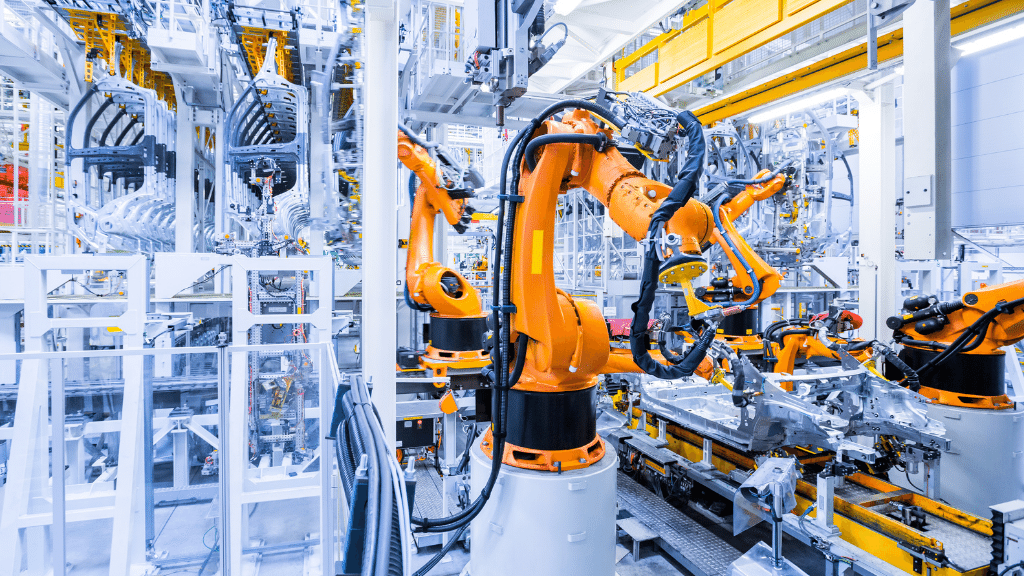

Automation & Robotics are becoming common in the manufacturing plant industry, with general industry and automotive parts suppliers leading the way.

The expected benefits have contributed to an increased number of automation and robot installations, but the unexpected benefits have rapidly accelerated the pace of those installs.

When implementing an industrial or collaborative robot, manufacturers expect several common benefits. From reduced operating costs related to energy and waste to improved quality, consistency and production rates, robots help companies to be more competitive and more flexible while improving employee health and safety. After implementation while monitoring the ROI though, several unexpected benefits have been recognised, helping realise that return in even six to twelve months.

Maintenance Benefits

The addition of a robotic system to a manufacturing facility at first may seem complex, after installation many have seen a decrease in maintenance costs. Facilities with robotic installations achieve higher yield and throughput, upstream production lines have on occasion been able to shut down more frequently to allow for preventative maintenance tasks, avoiding expensive downtime from unplanned maintenance. Additionally, where additional staffed equipment may have been added previously to widen the production bandwidth, the improved efficiency with a robot may allow that floor space to be regained for other production needs.

Collaboration Benefits

When a worker may be in close proximity to a robot, specifically a collaborative robot, a worker’s idle time has seen instances of reduction. Generally Collaborative robots (COBOTS) are deployed for repetitive lightweight tasks such as part retrieval or simple holding of key parts for an operator. COBOTS generally are used in common labour, with the initial ideas for the robot coming from the manufacturing plant staff they assist.

Employee Turnover Benefits

Another one of the larger unexpected benefits has been a reduction in employee turnover. Initially, employees tend to be concerned for their jobs when robotic labor is introduced to their workplace. However, based on the implementation, the investment in the new technology also proves to be an investment in the employees. In most cases, the robots are aiding in tasks that are repetitive and physically demanding. The existing workforce knows the process, knows what the quality and production requirements are, and can usually be trained to then monitor and operate the robot cell. In turn, the employees have reduced physical fatigue, mental fatigue, and accidents.

Job Creation Benefits

Finally, in many part production facilities, robots have added capacity and even increased the number of jobs. Not only from more technical workers able to modify robot programs and paths, but production and shift managers as well. Skilled workers still tend to be more productive for short part runs with high changeover rates during day shift production, but with the ability for robots to be setup for hours of unmanned production, additional shifts can be added, increasing overall capacity. Day shift operates as normal–focused on short part runs or more complex parts that are not easy for a quick robot setup–then sets up production to be run unattended by the robot during night shift. A shortened third shift can then complete robot production and clear the work cell for day shift.

In summary, the cost of robotic automation has been dropping sharply over the past 10 years, making them more financially affordable with greater long-term savings, plus a host of benefits that may not have even been previously considered.

With the newest robots available on the market, even small- to medium-size enterprises can improve productivity, efficiency, and even employee health, safety, and motivation.

To discuss your specific requirements, contact us.

.png?width=190&name=IPA%20Logo%20Transparent%20(Hi-Res).png)