Infrared Training for Condition Monitoring

As a trainer, I am fortunate enoughto work with people from all industries and walks of life.

During this period of training people for my own

Thermography inspection business through to the “open to the public” Thermography courses, I have confirmed what I have thought for a long time.AUTHOR: Jeff Erichsen

Advanced Infrared Resources Australia

There are many, many wonderful minds on the floor of a workshop. Unfortunately, I have watched apathy set in on some of these minds being born from 20 years of doing the same job with no stimulation. There are so many great technicians who do not want to climb the corporate ladder, yet are bored stiff with what they are doing on the floor and therefore are not sure what to do next.

There are many, many wonderful minds on the floor of a workshop. Unfortunately, I have watched apathy set in on some of these minds being born from 20 years of doing the same job with no stimulation. There are so many great technicians who do not want to climb the corporate ladder, yet are bored stiff with what they are doing on the floor and therefore are not sure what to do next.

Imagine my delight watching the penny drop, one by one, when they realise what this new concept and tool can provide them. Even more enjoyable perhaps, is watching the penny drop for those who already think they know about thermal energy and temperature and what it really means through the lens of a thermography camera. Certainly there are those who are stubborn, abrupt, critical and there are the one or two that are just there to have an easy week funded by the company they work for, and boy, don’t they get a shock. However, it is our job as trainers to do as our job title describes…..train them with enough of a combination of enthusiasm, knowledge and relatable experience to turn them around, switch them on, and open their minds to the possibilities of this.

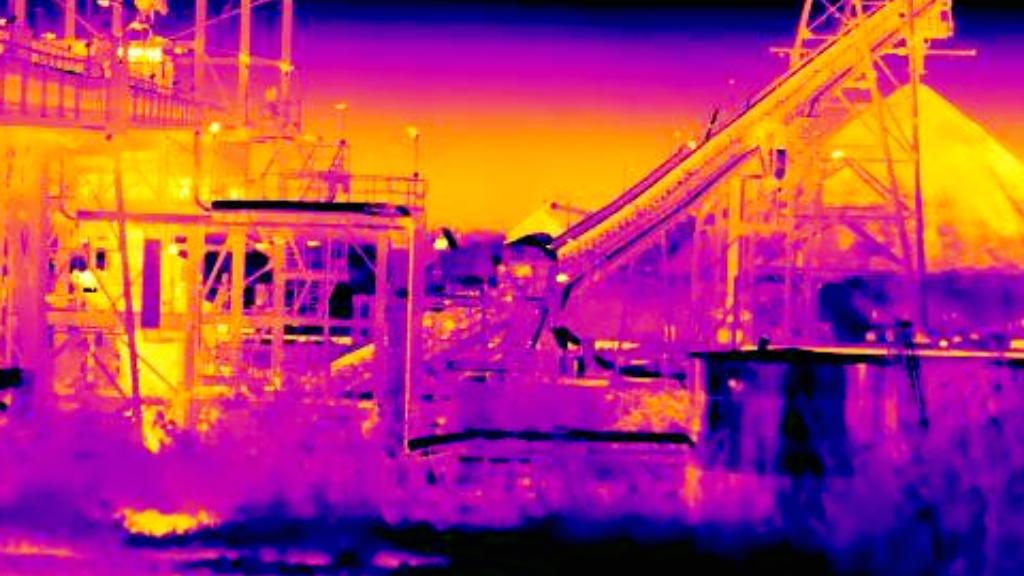

Temperature differential between final drives on a Cat 793 Haul Truck.

There are 3 main industries that are represented in our thermography courses.

Electrical – which accounts for 90% or more of the participants in Category 1 courses due to the enlightenment of insurance companies, that are not only

beginning to mandate that commercial and industrial electrical switchgear and installations should be inspected using thermography every 12 months (following America’s NFPA), but to ensure they ask that the thermographer is suitably qualified.

Mechanical – vibration analysis has always, and will always be, the king pin in condition monitoring due to its predictive ability when it comes to mechanical components. However due to the versatility, ease of use, speed and early fault detection capabilities of infrared thermography, not to mention its application to areas where you cannot hope to stick a vibration sensor, there is an upward trend in technicians attending courses to learn about mechanical applications.

Building –The Australasian building industry finally appears to be catching up with the rest of the world, which uses thermography in many building applications such as detecting moisture ingress, insulation inspections and in conjunction with blower door testing for building air tightness.

However, as I travel around the Australasian region, I am gaining an understanding that Infrared Thermography as a condition monitoring tool is still one of the most misunderstood and under-utilised disciplines in the condition monitoring suite.

Why? My opinion; based on the observations I have made and discussions I have had in the past 6 years can be summed up in the following points:

- Most already think they know about Thermography because they have been using spot radiometers for the last 25 to 30 years. (I was one of them)

- Most think the camera does all the work (It is just point and shoot).

- Everybody thinks Thermography is about temperature.

- In summary, they don’t know what they don’t know as it is a lot like not being able to see the forest for the trees.

However, the combination of industry stalwarts and those of us who are breaking new ground, there is an awakening that is seeing an increase in thermal imager sales and the training that goes with them.

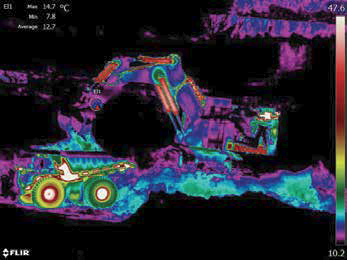

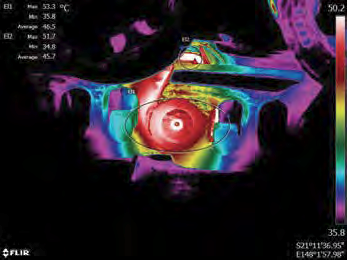

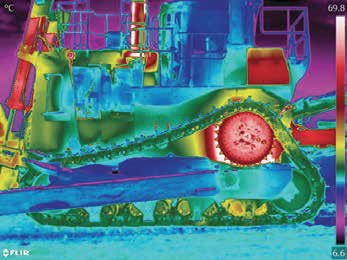

Monitoring a Cat 6060 during operation. Failing bulldozer track pin – too late to save.

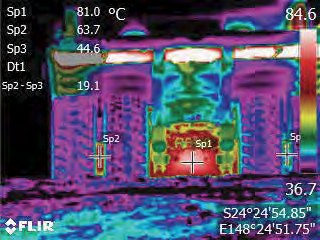

Visual image of a Cat D10T Bulldozer. IR image of a Cat D10T Bulldozer on Auto – can you pick the anomalies.

Additional Challenges in Industry

With many mangers beginning to understand the value of adding IR to their maintenance program, they are unfortunately restrained by budget, lack of knowledge and fear of funding concepts that may not bear fruit.

The key mistake here is the lack of training and consultation with industry experts and so goes the old saying, if you fail to plan, plan to fail.

It is often euphoric when an infrared camera is purchased (albeit cheap and not fit for purpose) and sometimes; someone is even trained, which usually consists of a half or one day training session that the salesperson who sold the imager supplies. A program is started and often turns to stagnation when this is not followed up with an audit or someone to mentor the program along.

I would say that 95% of the sites I visit have a thermography camera and of them, 99% do not know how to use them. Of the remaining 1% when asking the questions around the detail of their program, there are a lot of blank looks.

But…..the light bulb is slowly switching on due to the persistence of may dedicated individuals and more importantly; this enlightenment is coming about by education from industry user groups like the Australian Professional Thermography Association (AUSPTA), a not for profit organisation who’s executive, committee and members have tirelessly lobbied industry groups to come to the understanding that thermography, despite some manufacturers claims, is not a “point and shoot discipline”.

Australasian industry, which includes large companies that both engage sub-contract thermographers and/or employ thermographers, end users such as SME’s, medical andAn important step in this enlightenment has been the co-operation between the Australian Institute of Non-Destructive Testing (AINDT) and AUSPTA around the concept of certification.

veterinarian user groups, and mediators such as insurance companies, are all beginning to come together on this subject. While it is fantastic that we train people in the

discipline, which is where everybody needs to start, where we need to end up is with some sort of audit that confirms that we are actually doing what we are trained to do, just

as a program should be audited.

Think about it, in every other trade, we are taught, we are mentored, we are continually audited by our tradespeople, we return to trade school and we are checked that our theoretical knowledge and practical knowledge are adept enough to be signed off as a tradesman, so why should it be any different for Thermography?

Where to now?

With the advent of drones, automation and the IoT (Internet of Things), many say the end is nigh and to a certain point it may be; as there are many who hold the

reigns who say that data is king.

My opinion? There is still a great need for the trained and skilled technician for the following reasons:

- In the case of drones, we are already seeing a sharp increase in those buying a thermal camera and bolting it to their drone and calling themselves Thermographers

and their work is; let’s just say; questionable. The machine learning aspect of the various software available cannot account for or detect reflected energy which causes a false positive or negative in the image, so there is going to be a lot of waste of time and replacement of components when it comes to “Hot Spots” or “Cold Spots”. - Data does not smell, feel and listen, which is a very important part of any reliability technician’s job.

- There are many in industry who are projecting that in the future there will be a shortage of maintainers who have the multiple of skills required to diagnose the automated equipment, whether that be a production line, robotics, or automated mining equipment. Yes; this equipment is and will be loaded with sensors, however nothing is perfect, nor is it failsafe and therefore a skilled technician armed with this multi-disciplinary tool will be able to identify, monitor and greatly assist in the diagnosis of many electrical and mechanical issues.

From my observations, while many companies are preaching predictive and proactive maintenance, they are ignoring the elephant in the room and that is that their current procedures still rely heavily on preventative maintenance tasks and their current workforce is under trained to assist in making the step between PM and PdM.

Through CMMS systems like SAP, maintenance is still heavily revolving around time-based tasks, which have been proven for many years to be inefficient, and even the cause of more failures then they prevent, and let’s not mention the waste of perfectly good oil for example, that could have been filtered, tested and re-used.

Let’s us also not forget that there are a lot of industries that are far off automation, yet have intelligent, proactive employees, who with a little bit of encouragement and

upskilling will be future ready.

In Summary

The near future of condition monitoring, training and certification in Infrared Thermography and any other CM tools for that matter, I would say looks pretty bright! One of my most influential mentors Mr. Wayne Ruddock from Canada has been teaching thermography since 1980. He has travelled the world teaching this discipline and according to him, he has never been so busy in his life, which is a little unfortunate for him as he is moving towards his 70th birthday.

As far as I am concerned, I have been fortunate enough to be trained and mentored by some of the most experienced and knowledgeable Thermographers nationally and internationally and each one of them has passed their own little piece of passion for Thermography on to me. It is my job to do the best that I can to pass the knowledge that I have onto the next generation of thermographers.

.png?width=190&name=IPA%20Logo%20Transparent%20(Hi-Res).png)