Critical Thinking for Problem Solving

Training Provider: Industry Partners Australia

Delivery Method: Public, On-site

You have a formalised problem-solving process used in your organisation, but ask yourself, do you have effective problem solvers in every area of your business?

Are your teams resolving the minor issues before they escalate into serious issues?

Is your problem-solving process creating a great culture of collaboration and teamwork and is it really working for you?

We have seen multiple approaches to the methodology of problem-solving in industry with varying levels of success. The missing element is often effective facilitation of the problem-solving process and knowledge of critical thinking within the problem-solving teams.

It is well recognised that the ability to “think critically” falls within the top five skills for the future.

Critical thinking when problem-solving is a learned behaviour that will benefit your business, and more importantly, your valued employees.

What Will I learn:

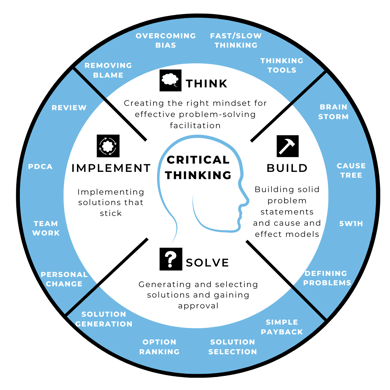

“Critical Thinking for Problem Solving” is a 1-day program developed by Industry Partners Australia around the facilitation of problem-solving, bias recognition, developing problem clarity, logical reasoning, solution generation and selection techniques.

We have created an interactive and enjoyable format that allows participants to learn in an open and engaging environment. We will guide participants in developing their skills because we passionately believe that problem solving is an opportunity, not an imposition.

Our educators have practical problem-solving experiences to draw upon. In addition, we have seen first-hand how vital correct problem-solving facilitation is to creating success.

What Outcomes will the training provide?

- Understand the elements of thinking critically.

- Be able to identify and act on common cognitive biases that exist in problem-solving teams.

- Lead teams towards clarity and alignment on problem understanding.

- Learn the secrets to leading effective brainstorming.

- Effectively educate others on developing correct cause and effect chains.

- Think like a business owner when selecting potential solutions.

Who will benefit from attending this training?

Front line employees involved in problem-solving. People leading problem-solving teams who wish to become more effective and those starting on their problem-solving journey.

What is the duration of this training?

This program is delivered over one full day.

Training Overview

Lean Six Sigma is a systematic approach to continuous improvement achieved by removing wasteful non-value-adding activities and reducing process variation. The methodology, tools and frameworks can be applied to any industry and to any workplace, delivering improvements in quality, service outcomes, customer satisfaction, revenue and margins, and strengthening organisational culture.

Lean Six Sigma Belts provide recognition for an individual on their awareness and understanding of Lean and Six Sigma concepts. A Belt holder in an organisation can be expected to help achieve higher performance and sustain competitive advantage.

Efficiency Works’ Lean Six Sigma Belts’ program, which is delivered entirely online through our Learning Management System Portal, provides graduated learning of the knowledge components required for Yellow Belts, Green Belts and Black Belts.

Belts are a good steppingstone to ‘Competitive Systems and Practices’, the only accredited Lean Six Sigma training recognised in Australia.

What will I learn?

The following knowledge components are included and increase in complexity from Yellow up to Black Belts:

- Six Sigma principles

- Six Sigma history and application

- Other process improvement tools

- Lean and Six Sigma Concepts

- Quality tools

- Metrics and measurement systems

- Selecting projects

- DMAIC/DMADV Problem Solving

- Statistics and hypothesis testing

- Control charts

- Statistics in business applications

- Analysis of variance

- Design of experiments

- Lean Six Sigma application in various fields

What outcomes will the training provide?

Yellow Belts: Familiar with the fundamental tenets of Lean Six Sigma concepts, an understanding of the overall methodology, basic data collection, the language of hypothesis testing and measurement systems. Typically, Yellow Belts are not regular members of a process improvement team but need to contribute towards Lean Six Sigma projects.

Green Belts: Work within Lean Six Sigma teams, deliver or lead small projects on their own, help Black Belts apply tools to larger projects, and undertake most of the statistical data collection and Lean tool deployment.

Black Belts: Possess a thorough understanding of all aspects of the Lean Six Sigma methodology, tools and frameworks. Lead process improvement projects, provide strategic input to business improvement programs and projects, and guide Green Belts in project delivery.

Online learning for Lean Six Sigma Belts courses deliver the following outcomes for successful participants and for the organisation:

- A fundamental understanding of Lean Six Sigma methodology, tools and frameworks

- Lean Six Sigma knowledge components that can be deployed to undertake improvement projects

- An understanding of how data analytics can improve decision-making

- A platform to develop a Continuous Improvement culture

- Recognition of your knowledge at Lean Six Sigma Yellow Belt, Green Belt or Black Belt levels

Who will benefit from this training?

The Lean Six Sigma methodology, tools and frameworks can be applied to any work environment where business/continuous improvement and the resulting outcomes are a strategic imperative.

The knowledge components of these courses will help address the needs of professionals who are involved in identifying, delivering, managing and leading continuous improvement projects.

These courses are suitable for:

- Executive Managers

- Senior Managers

- CI / BI Managers

- Lean Six Sigma Champions

- Team Leaders and Supervisors

- Business and process analysts

- IT staff

- Employees who need to incorporate Lean Six Sigma into their working day

What is the duration of this training?

Yellow Belt = 1 - 3 weeks

Green Belt = 1 - 6 weeks

Black Belt = 1 - 3 months

.png?width=190&name=IPA%20Logo%20Transparent%20(Hi-Res).png)